How 「 WAREHOUSE ROBOT PORTER 」 Enhances Operational Efficiency

HOW WAREHOUSE ROBOT PORTER Collaborates In Order Picking

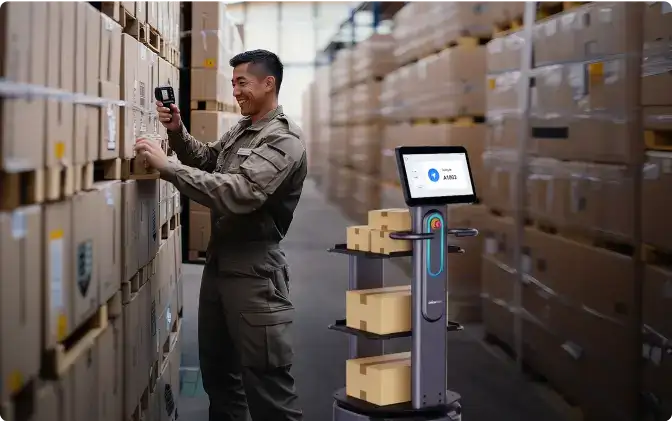

Route-Optimized Multi-Picking

Robots can visit simple or multiple pick-up points in one trip, take the shortest route, then head straight to shipping area.

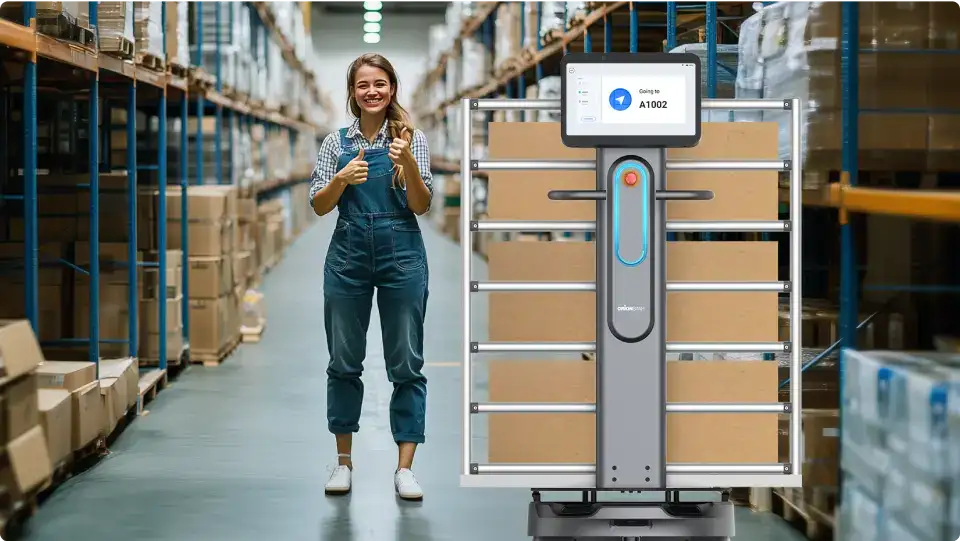

Smart Follow picking

Robots can intelligently recognize and follow operators, stopping and moving as needed, freeing employees' hands and reducing physical strain.

Flexible & Scalable Delivery

Versatile attachments handle goods of different sizes and shapes, adapting to various industries. Additionally, speed adjusts based on environment and load for optimal performance.

Quick Deployment & Simple Operation

The robot's user-friendly design ensures that both staff and external operators easily get started. With a rapid deployment process, it can be set up and ready for duty on the same day.

Multi-Robot Cooperation

Orionstar robots enable multiple robots to work simultaneously, intelligently prioritizing tasks to enhance warehouse efficiency.

What are the Benefits

Increase Production Efficiency

By planning optimal picking routes and automating order fulfillment, workers can focus more on picking tasks, increasing order picking productivity by 2-3x.

Enhance Employee Satisfaction

Workers are relieved from pushing heavy manual carts, reducing labor intensity and decreasing labor turnover rates.

Optimize Accuracy

By integrating with warehouse management systems, robots can minimize human errors, leading to more accurate inventory management and order fulfillment.

Improve Safety

Robots can transport heavy loads and operate stably in complex warehouse environments, effectively reducing collisions with goods and personnel, thus enhancing overall safety.

Robot Porter: the “indispensable assistant” in e-commerce warehouse

Traditional cart-picking is time-consuming and strenuous, reducing efficiency and impacting order processing and customer satisfaction.

During peak seasons, surging orders and staff shortages challenge sales growth.

Achievement

- The intelligent follow mode frees up human pickers’ hands, significantly reducing physical exertion.

- Robot porters integrate with the ERP system, doubling order efficiency with dual pallets.

- 6 robot porters work 21 hours daily, handling peak orders and boosting sales with ease.

How WAREHOUSE ROBOT PORTER Collaborates in Order Fulfillment

Just-in-Time Transportation

Robots ensure orders are delivered on time, maintaining a seamless workflow and avoiding delays.

Durability & Reliability

Designed for continuous operation, robots tirelessly travel between the warehouse and shipping area, ensuring constant order fulfillment.

Multi-Robot Collaboration

Supports multi-robot working simultaneously, optimizing delivery processes. Robots automatically detect obstacles and optimize navigation paths for efficient, safe, and accurate transport in mixed environments.

High Load Capacity

Equipped with various attachments, robots can handle items of different shapes and sizes, enhancing carrying capacity for smooth order fulfillment.

Smart Summon Delivery

Press the call button and robots will promptly navigate to the designated location to offer assistance, ensuring delivery needs are met at any time.

What are the Benefits

Increase Efficiency

Robots streamline the transfer process by optimizing routes and working continuously without breaks, ensuring faster operations.

Alleviate Employee Stress

By handling repetitive and strenuous tasks and reducing walking distances, robots allow employees to concentrate on more important work, thereby decreasing labor turnover rates.

Improve Safety

Robots can handle heavy loads and operate in potentially hazardous environments, reducing the risk of workplace injuries.

Robot Porter: “shuttle vehicles” in warehouse

A French auto parts store uses a front-shop, back-warehouse structure. The front desk is responsible for customer service and synchronizes orders in real-time with the back warehouse, where staff quickly pick and deliver items to the store. The speed of order fulfillment directly affects customer wait times, so improving the efficiency and accuracy of order picking is crucial for enhancing customer satisfaction.

Achievement

- Using robot porters, the warehouse can streamline roles, allowing salespeople to focus on customer service and pickers to concentrate on order fulfillment without worrying about transportation. These robots handle heavy transport tasks, reducing employee workload and ensuring quick order processing.

- With autonomous navigation, robot porters efficiently navigate complex aisles, minimizing collision risks and enhancing the safety of personnel and goods, thereby improving warehouse security.