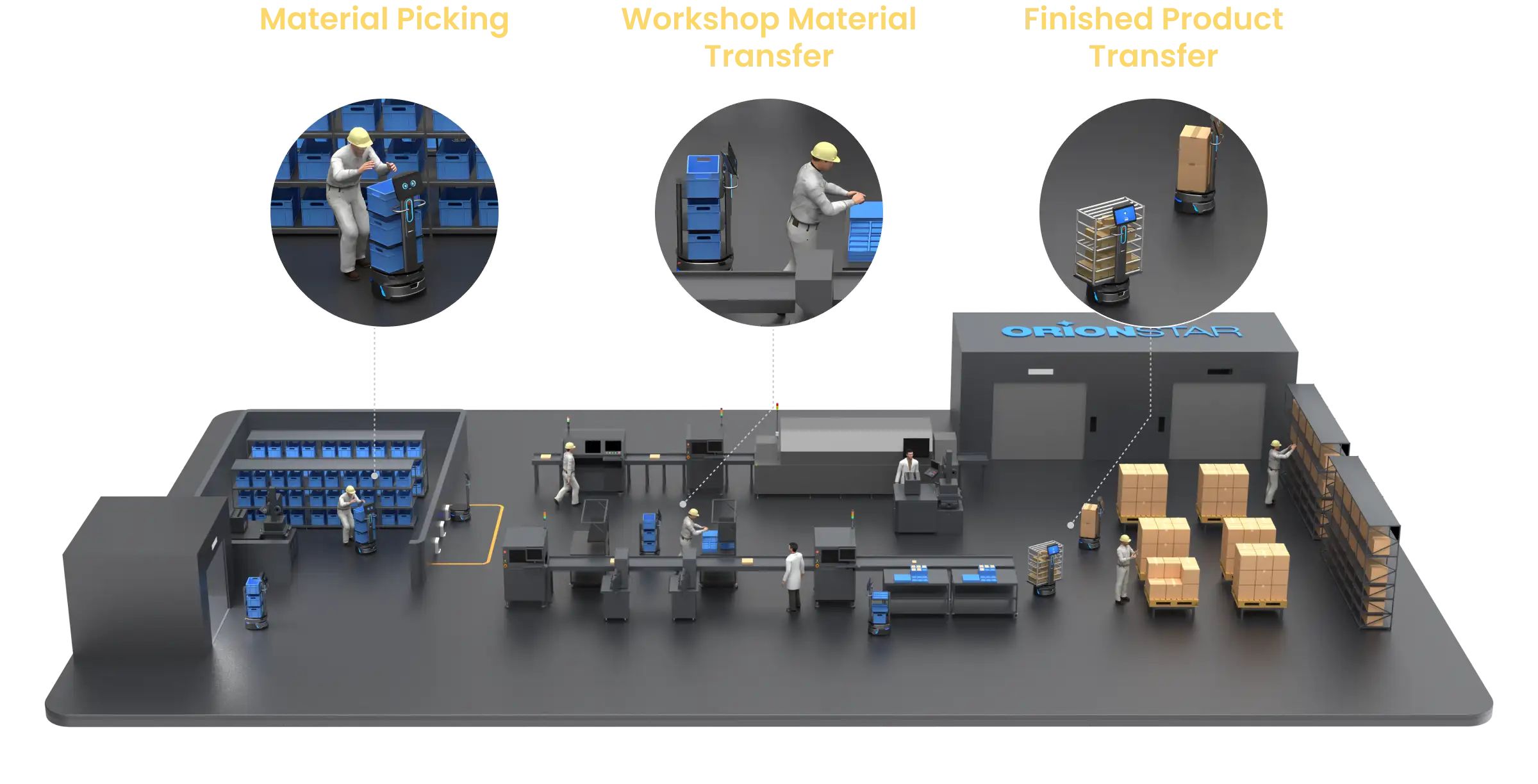

How 「 FACTORY ROBOT PORTER 」 Enhances The Production Process

HOW FACTORY ROBOT PORTER Collaborates In Material Picking

Route-Optimized Multi-Picking

Robots visit multiple pick-up points in one trip, taking the optimal route, and then proceed directly to the assembly area, ensuring efficiency and precision in the operation.

Smart Follow picking

With visual perception for accurate identification, robots are designed to follow operators, easing the picking process with automation to enhance efficiency and precision.

Flexible & Scalable Delivery

Diverse attachments fit goods of various sizes and shapes. Speed can be adjusted according to the environment and load requirements to achieve optimal delivery performance.

Quick Deployment & Simple Operation

The robot's user-friendly design ensures that both staff and external operators easily get started. With a rapid deployment process, it can be set up and ready for duty on the same day.

Multi-Robot Cooperation

Multi-robot can collaborate seamlessly, integrating with RCS to automatically manage tasks assigned by MES. Robots can adjust their operational speed to suit any environment, ensuring an optimized workflow.

Smart Summon Delivery

Press the call button and robots will promptly navigate to the designated location to offer assistance, ensuring delivery needs are met at any time.

What are the Benefits

Increase Production Efficiency

Robots enhance transportation efficiency from the warehouse to the production line, ensuring a continuous supply of materials.

Alleviate Labor Shortage Issues

Robots handle repetitive transportation tasks, mitigating the impact of insufficient manpower on production.

Reduce Worker Fatigue

Robots handling errands reduce the need for workers to frequently get up to fetch and deliver materials, allowing them to focus on their own tasks.

Factory Robot Porters handle the delivery, freeing workers to innovate

Korea’s Printing Factory is renowned for its high-quality buttons and stickers, producing up to 5,000 units daily. The printing process includes four key steps: cutting, button making, trimming, and packaging. Material handling between these steps is crucial to ensure seamless and efficient production.

Achievement

- Human-robot collaboration allows Factory Robot Porters to handle material transport, letting workers focus on production, significantly boosting efficiency and quality.

- Factory Robot Porters, using autonomous navigation technology, effectively reduce the risk of foot injuries, greatly enhancing safety.

How FACTORY ROBOT PORTER Collaborates In Workshop Material Transferring

Just-in-Time Replenishment

Robots ensure materials are restocked promptly, maintaining a seamless workflow without delays.

Efficient Round-Trip Operation

Robots perform repeated journeys along the workshop, efficiently transferring materials from the supply point to the line, enhancing overall productivity.

Endurance & Reliability

Designed for continuous operation, robots tirelessly travel from the start to the end of the production line, ensuring constant material supply.

Quick Deployment & Simple Operation

The user-friendly design ensures that both staff and external operators easily get started. With a rapid deployment process, it can be set up and ready for duty on the same day.

What are the Benefits

Improve Production Efficiency and Continuity

Robots facilitate prompt restocking, guaranteeing a seamless material supply from the start to the finish of the production line, preventing work stoppages, and significantly improving production efficiency and process continuity.

Improve Job Satisfaction

Robots take on repetitive handling tasks, reducing miscellaneous duties for workers, allowing them to focus more on production and other meaningful tasks, thereby enhancing job satisfaction and work efficiency.

Factory Robot Porters offer flexible distribution, optimizing the entire production process

Dongguan, as the “world’s factory,“ produces 1/4 of the world’s smartphones and 3/4 of the computer motherboards. With declining demographic dividends, rising labor costs, and global economic fluctuations, there’s an urgent need for intelligent upgrades to reduce costs and increase efficiency.

Achievement

- Deploy Factory Robot Porters for warehouse picking, production delivery, and product transfer, creating an ”automated dispatch chain.

- “Factory Robot Porter requires no track laying, enabling same-day deployment and immediate operation.

How FACTORY ROBOT PORTER Collaborates In Finished Product Transferring

Heavy-Duty Lifting

The robots are designed to handle the movement of bulky finished products, eliminating the need for manual labor and ensuring a safe and efficient workflow.

Dynamic Obstacle Avoidance

With advanced technology, the robots precisely navigate the factory environment, safeguarding both workers and goods.

Quick Deployment & Simple Operation

Diverse item-carrying accessories accommodate goods of various sizes and shapes. Speed can be adjusted according to the environment and load requirements to achieve optimal delivery performance.

What are the Benefits

Ensure Safety

Reducing the risk of worker injuries from heavy lifting, preventing the risk of cargo falls during transportation, ensuring workplace safety.

Reduce Worker Fatigue

Robots assist in handling heavy loads, reducing the physical strain on workers from repetitive and high-intensity tasks, effectively diminishing physical exertion and fatigue, and enhancing work comfort and productivity.

Factory Robot Porters handle cross-regional material delivering

Pearl Global is a leading multinational apparel manufacturer focused on sustainability and innovation, with factories in India, Bangladesh, Vietnam, and Indonesia.

Achievement

- Factory Robot porters automate material transport, improving efficiency and ensuring smooth production line operations.

- Factory Robot porters reduce errors from manual handling, lower costs and boost overall efficiency.

- Factory Robot porters free workers from tedious transport tasks, allowing them to focus on production, enhancing overall productivity and ensuring timely order delivery.